TAKAOKA SEISAKUSHO

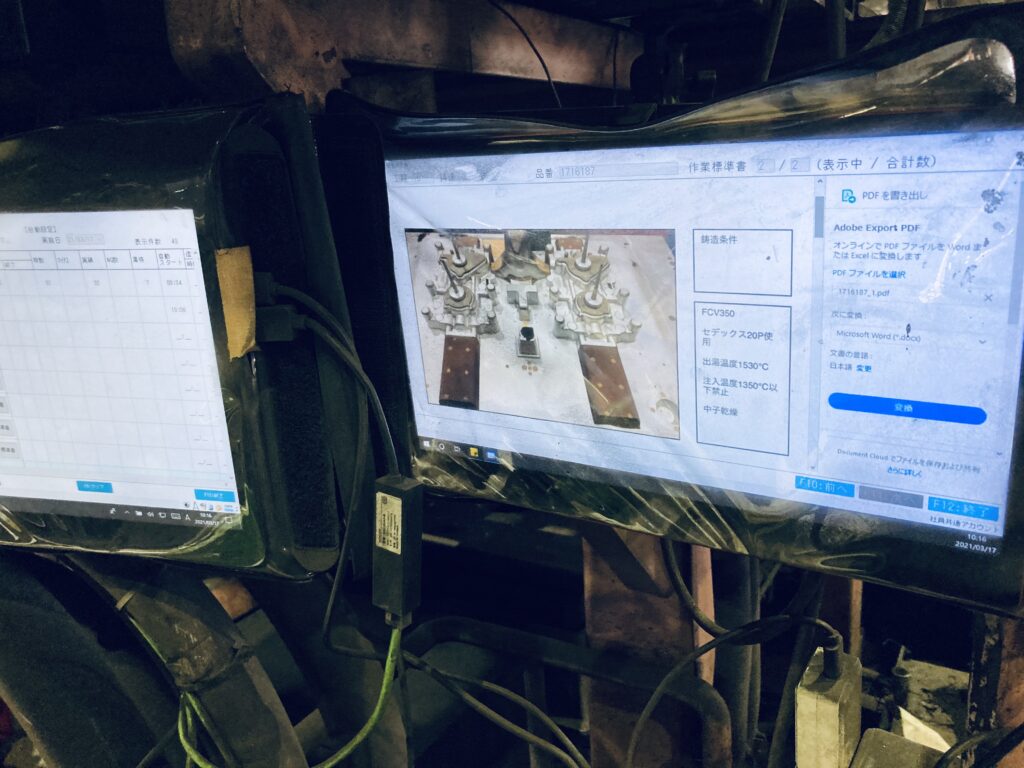

Takaoka Seisakusho co., Main Factory

123-14 Yokkaichi Takaoka Toyama Japan

9330351

TEL. 0766-31-5455

FAX. 0766-31-5456

Takaoka Seisakusho co., Second Factory

109-27 Yokkaichi Takaoka Toyama Japan

9330351

TEL: 0766-53-5914

FAX: 0766-53-5924