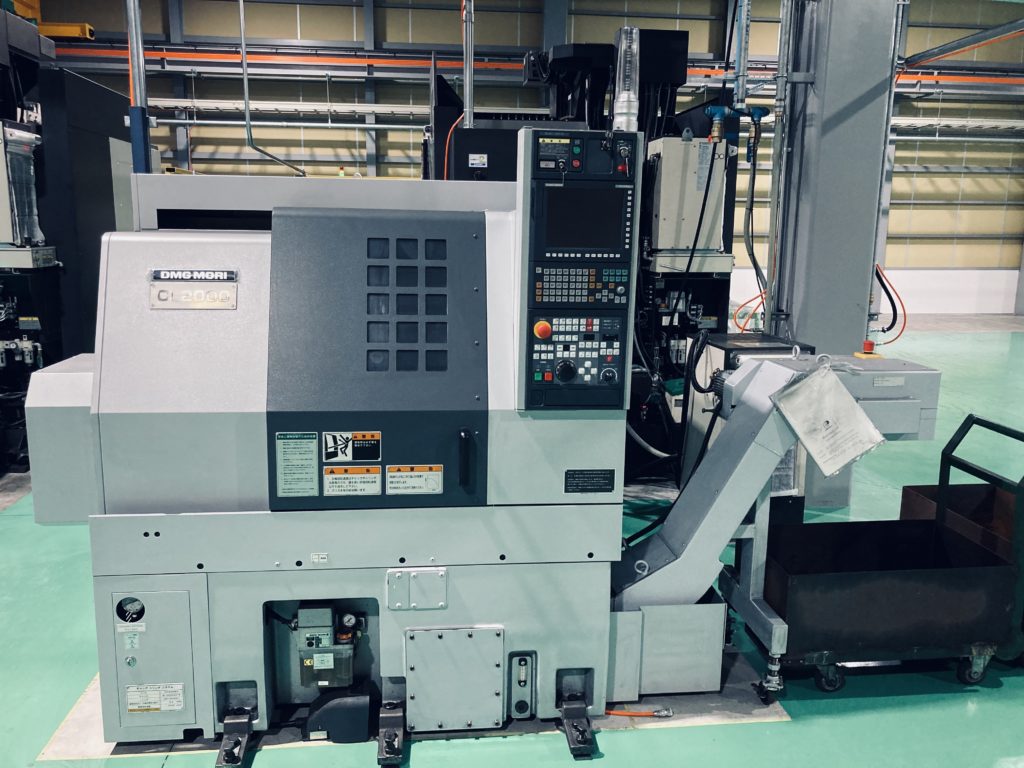

We have introduced a system [vacuum filtration device] that allows the cutting fluid of multiple machine tools to be filtered and pumped to each machine tool. This makes it possible to always use clean cutting fluid for machining, which leads to stable machining accuracy and extension of tool life. In terms of work, the operator no longer has to perform regular water supply work, change cutting water once a year, and clean the tank. We are always making management efforts to deliver the best products to our customers at low cost and high quality.